Pointek CLS200 – Digital

Contact

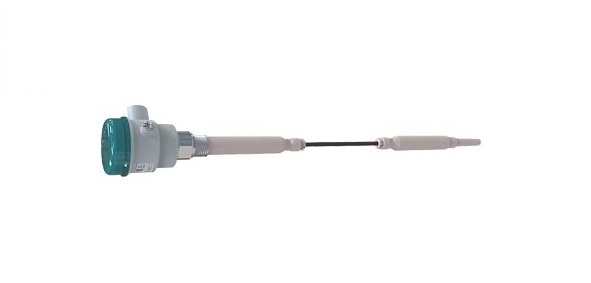

Pointek CLS200 (digital version) is a level switch for liquids, solids, slurries, foam, and interface detection. It features an LCD display, PROFIBUS PA communication, and supports optional rod or cable probe configurations.

Categories: Level, Point Level Measurement, RF Capacitance

Brand: Siemens

Key Features

-

Fully potted electronics, providing protection from shock, vibration, humidity, and condensation

-

High chemical resistance with probe constructed from stainless steel and PPS (optional PVDF)

-

Operates independently of vessel or pipe grounding—ideal for use in plastic or concrete tanks

-

Immune to material buildup thanks to high-frequency oscillation

-

High sensitivity, suitable for media with a dielectric constant ≥ 1.5

-

Integrated LCD display with menu-driven interface for easy configuration

-

PROFIBUS PA digital communication (Profile 3.0, Class B), compatible with SIMATIC PDM software

-

Galvanically isolated power supply, accepts 12 to 30 V DC

-

Supports configuration of alarm behavior, signal delay, and precise switching point

Typical Applications

-

Level detection in liquids, slurries, and foams

-

Suitable for powders, granules, and bulk solids

-

Ideal for pressurized systems or hazardous area installations

-

Excellent performance in non-conductive tanks (e.g., plastic or concrete)

-

Seamless integration into PROFIBUS-based systems for remote diagnostics and configuration

Additional Information

When used with a thermal isolator, the wetted part of the probe can withstand process temperatures up to 125 °C (257 °F). The sensor can be configured to detect either pre-contact proximity or direct contact with the material. PROFIBUS network integration enables full access to diagnostic capabilities and remote operation via SIMATIC PDM.

| Category | Specification |

| Mode of operation | Inverse frequency shift capacitive level detection |

| Input | — |

| Measured variable | Change in picoFarad (pF) |

| Output | — |

| Output signal | Solid-state output |

| Output type | Galvanically isolated |

| Protection | Against reversed polarity (bipolar) |

| Max. switching voltage | 30 V DC / 30 V peak AC |

| Max. load current | 82 mA |

| Voltage drop | < 1 V, typical at 50 mA |

| Time delay (ON and/or OFF) | Programmable by user (0 … 100 s) |

| Fail-safe mode | Min. or max. |

| Connector type | Removable terminal block |

| Rated operating conditions1) | — |

| Installation location | Indoor / outdoor |

| Ambient conditions | — |

| Ambient temperature | -40 … +85 °C (–40 … +185 °F)2) |

| Storage temperature | -40 … +85 °C (–40 … +185 °F) |

| Installation category | II |

| Pollution degree | 4 |

| Medium conditions | — |

| Compatible media | Liquids, bulk solids, slurries, and interfaces |

| Minimum dielectric constant εr | ≥ 1.5 |

| Process temperature | — |

| Without thermal isolator2) | -40 … +85 °C (–40 … +185 °F) |

| With thermal isolator | -40 … +125 °C (–40 … +257 °F) |

| Process pressure | — |

| Rod version | -1 … +25 bar (–14.6 … +365 psi) g (nominal) |

| Cable version3) | -1 … +10 bar (–14.6 … +150 psi) g (nominal) |

| Sliding coupling version | -1 … +10 bar (–14.6 … +150 psi) g (nominal) |

| Design | — |

| Enclosure material | Epoxy-coated aluminum with gasket |

| Optional thermal isolator | 316L stainless steel |

| Electrical terminal | Removable terminal block, max. 2.5 mm² |

| Degree of protection | IP65 / Type 4NEMA 4 (optional IP68) |

| Cable entry | 2 × M20 × 1.5 thread (option: 2 × ½″ NPT, 1 plugged by default) |

| Electromagnetic compatibility | To comply with CE EMC regulations (where applicable); install per manual |

| Power supply | — |

| Bus voltage (standard) | 12 … 30 V DC |

| Bus voltage (intrinsically safe) | 12 … 24 V DC |

| Current consumption | 12.5 mA |

| Certificates and approvals | — |

| General purpose | CSA, FM, CE, RCM |

| Dust ignition proof | ATEX II 1 D T100 °C |

| Dust ignition proof with IS probe | CSA/FM Class II, Div. 1, Groups E, F, G CSA/FM Class III T4 |

| Flameproof enclosure with IS probe | ATEX II 1/2 G Ex d[ia] IIC T6 … T4 ATEX II 1 D T100 °C |

| Explosion-proof with IS probe | CSA/FM Class I, Div. 1, Groups A, B, C, D CSA/FM Class II, Div. 1, Groups E, F, G CSA/FM Class III T4 |

| Intrinsically safe | ATEX II 1 G Ex ia IIC T6 … T4 ATEX II 1 D IP6X T100 °C CSA/FM Class I, Div. 1, Groups A, B, C, D CSA/FM Class II, Div. 1, Groups E, F, G CSA/FM Class III T4 |

| Non-incendive | CSA/FM Class I, Div. 2, Groups A, B, C, D CSA/FM Class II, Div. 2, Groups F, G |

| Non-sparking | ATEX II 3 G Ex nA IIC T6 … T4 ATEX II 3 D IP6X T100 °C UKEX II 3 G Ex nA IIC T6 … T4 UKEX II 3 D IP6X T100 °C |

| Marine | Lloyd’s Register (ENV1, ENV2, ENV5) |

| Other | Pattern Approval (China) |

| Communication | PROFIBUS PA (IEC 61158 CP3/CP3.2) Bus profile: IEC 61158-2 MBP (IS) Device profile: PROFIBUS PA for Process Control Devices V3.0, Class B, FISCO field device |

Footnotes:

- When used in hazardous areas, operational limits must follow the relevant certificate. See CLS200 pressure/temperature curves.

- Thermal isolator must be used if the process temperature exceeds 85 °C.

- Pressure rating depends on temperature. See pressure/temperature curves.

- Intrinsically safe operation requires suitable power supply or barrier.

Related products

Capacitance switches

Contact

Continuous Level Measurement

Contact

Level

Contact

Level

Contact

Level

Contact

Continuous Level Measurement

Contact

Continuous Level Measurement

Contact

Continuous Level Measurement

Contact