SITRANS LH300

Contact

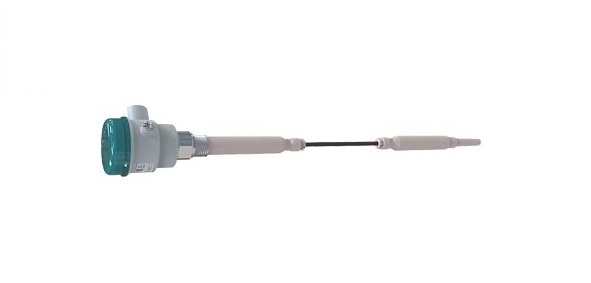

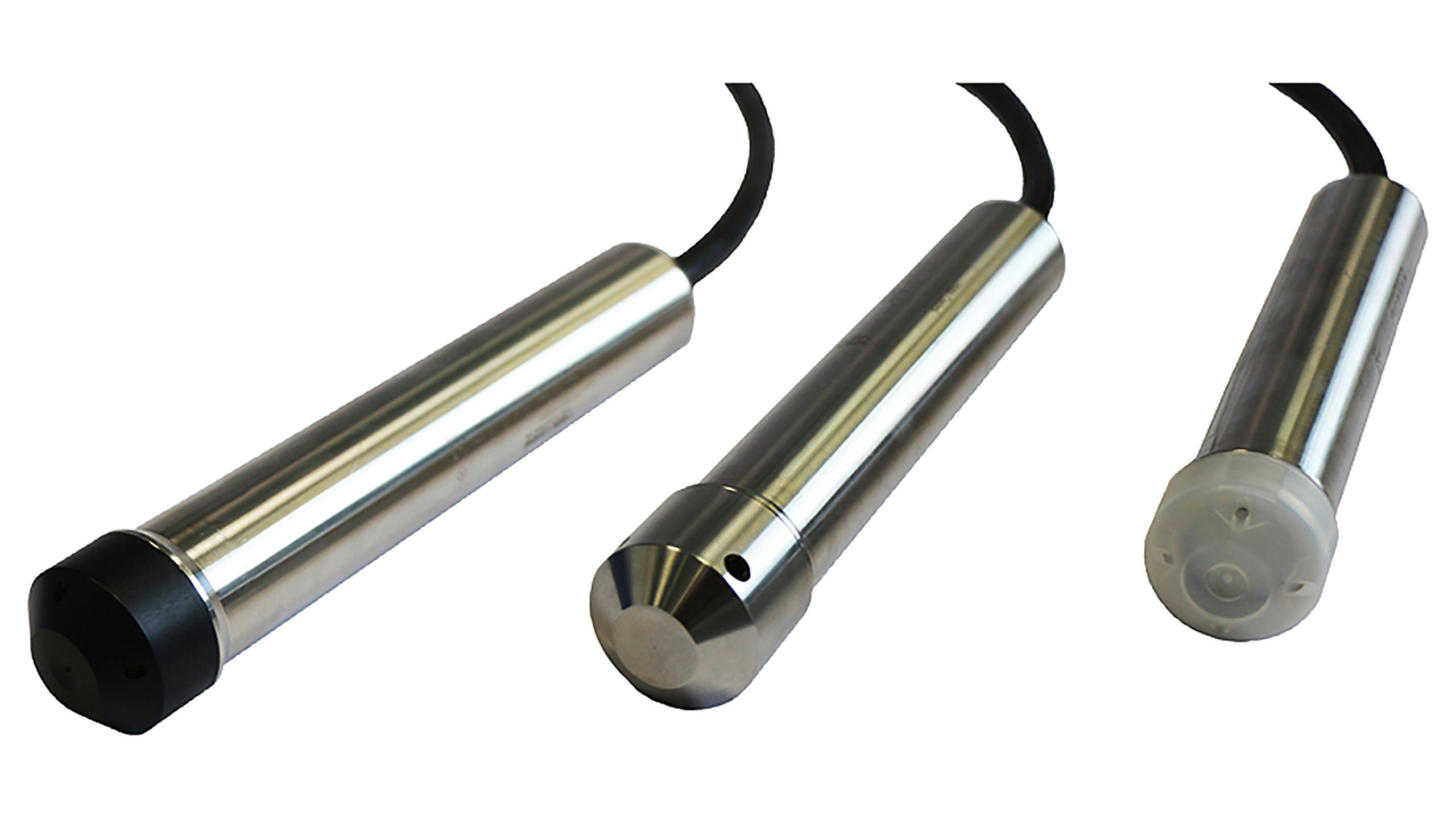

SITRANS LH300 is a submersible hydrostatic level sensor for measuring liquid levels in tanks, basins, channels, dams, and wells. It comes in PPE, stainless steel, or ETFE housings, with an optional explosion-proof version for hazardous areas.

Categories: Pressure, Single-range transmitters

Brand: Siemens

Key Features

-

Compact design for easy deployment in tight installation spaces

-

Simple mounting with included accessories: cable junction box and mounting clamp

-

High accuracy with a low error margin of ±0.15% of full span

-

IP68 protection rating, ensuring reliable operation under continuous submersion

-

Multiple housing material options:

-

PPE: lightweight and economical

-

Stainless steel: robust and impact-resistant

-

ETFE: chemically resistant, suitable for seawater or corrosive solutions

-

Typical Applications

-

Shipbuilding: level measurement in ballast and storage tanks

-

Water supply and wastewater treatment systems

-

Drinking water treatment facilities

-

Boreholes, open tanks, and non-pressurized vessels

-

Desalination plants handling seawater environments

Design and Construction

-

Employs a ceramic sensor with integrated Wheatstone bridge for high accuracy

-

Sensor and signal processing electronics are integrated within a stainless steel housing

-

Signal cable features a vented tube with moisture filter, allowing atmospheric pressure compensation and preventing condensation

-

Sensor membrane is protected by a dedicated impact- and debris-resistant cover

-

Equipped with full-range temperature compensation to maintain accuracy across varying ambient conditions

Mode of Operation

-

The hydrostatic pressure from the liquid column acts on the sensor membrane and is transmitted to the Wheatstone bridge within the ceramic sensing element

-

The difference between hydrostatic and atmospheric pressure is balanced through the vented tube integrated in the cable

-

The resulting voltage signal is amplified and converted into a standard 4–20 mA current output

-

Grounding cable is connected to the outer housing for electrical safety and noise suppression

| Category | Details |

| Mode of Operation | |

| Measuring principle | Piezo-resistive |

| Input | |

| Measured variable | Hydrostatic level |

| Measuring ranges – mH₂O | 0 … 1 mH₂O (0 … 3 ftH₂O) 0 … 2 mH₂O (0 … 6 ftH₂O) 0 … 3 mH₂O (0 … 9 ftH₂O) 0 … 4 mH₂O (0 … 12 ftH₂O) 0 … 5 mH₂O (0 … 15 ftH₂O) 0 … 6 mH₂O (0 … 18 ftH₂O) 0 … 10 mH₂O (0 … 30 ftH₂O) 0 … 20 mH₂O (0 … 60 ftH₂O) 0 … 40 mH₂O (0 … 120 ftH₂O) |

| Special ranges (on request) | – Up to 100 mH₂O (0 … 300 ftH₂O) – Up to 160 mH₂O (0 … 480 ftH₂O) |

| Measuring ranges – bar | 0 … 0.1 bar to 0 … 4 bar – Special: up to 10 bar and 20 bar |

| Max. permissible operating pressure | 1.5 bar for ≤ 0.3 bar / ≤ 9 mH₂O 2 bar for ≤ 0.6 bar / ≤ 18 mH₂O 5 bar for ≤ 1 bar / ≤ 50 mH₂O 10 bar for ≤ 2 bar / ≤ 100 mH₂O 20 bar for ≤ 4 bar / ≤ 200 mH₂O 24 bar for up to 240 mH₂O (720 ftH₂O) |

| Output | |

| Signal | 4 … 20 mA |

| Measuring Accuracy (IEC 62828-1) | |

| Deviation at limit incl. hysteresis & reproducibility | – Typical: ≤ 0.15% of full-scale – Max: ≤ 0.3% of full-scale |

| Effect of ambient temperature | ≤ 0.05% / 10 K (zero + span) |

| Long-term stability | ≤ 0.15% of full-scale / year (zero + span) |

| Operating Conditions | |

| Process temperature | –10 … +80 °C (14 … 176 °F) |

| Storage temperature | –20 … +80 °C (–4 … 176 °F) |

| Protection class | IP68 (IEC 60529) |

| Structural Design | |

| Weight | ≈ 0.4 kg (≈ 0.88 lb) |

| Cable | |

| Weight per meter | 0.08 kg/m (≈ 0.059 lb/ft) |

| Max hanging length | 300 m (990 ft) |

| Electrical connection | 2-wire with vent pipe and humidity filter |

| Materials | |

| Diaphragm | Al₂O₃ ceramic, 96% |

| Enclosure | Stainless steel: 1.4404 / 316L or 1.4539 / 904L (for seawater) |

| Gasket | – FPM (standard) – EPDM (optional) |

| Cable | – PE (standard/drinking water) – FEP (for aggressive media) |

| Protective cap | Stainless steel, PPE or ETFE |

| Auxiliary Power | |

| Voltage UB | 10 … 33 V DC (non-Ex) 10 … 30 V DC (Ex version) |

| Certificates & Approvals | |

| Drinking water (ACS) | 17 ACC NY 055 |

| EAC | TC N RU Д-DE.ПА02.B.05092 |

| UL (USA/Canada) | E344532, issued 2017-08-17 |

| Marine approvals | – Lloyd’s (LR): LR_18/20074 – DNV/GL: TAA00000CE – BV: 56926/A0 BV – ABS: HG1881314_P – RINA: ELE067319K |

| PED (2014/68/EU) | Not subject to pressure directive |

| Explosion protection | |

| ATEX | SEV 16 ATEX 0121 |

| IECEx | IECEx SEV 16.0003 |

| EAC Ex | TC RU C-DE.AA87.B.00324 |

| Intrinsic safety “i” | Marking: II 1 G Ex ia IIC T4 Ga |

Optional Accessories

Cable Box

| Use | For connecting the transmitter cable |

| Weight | 0.2 kg (0.44 lb) |

| Electrical connection | 2 × 3-way (28–18 AWG) |

| Cable entry | 2 × PG 13.5 |

| Housing material | Polycarbonate |

| Vent | Atmospheric pressure |

| Protection class | IP65 (IEC 60529) |

Anchoring Clamp

| Use | For mounting the transmitter |

| Weight | 0.16 kg (0.35 lb) |

| Material | Zinc-plated steel, polyamide |

| Terminal range | For cables Ø 5.5 … 9.5 mm |