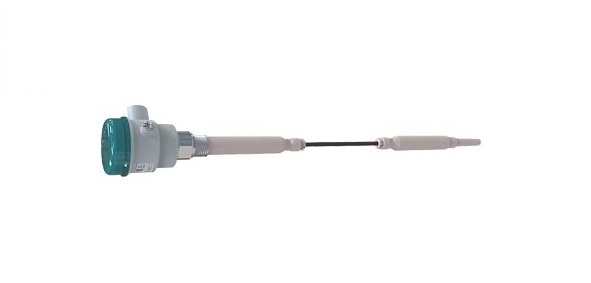

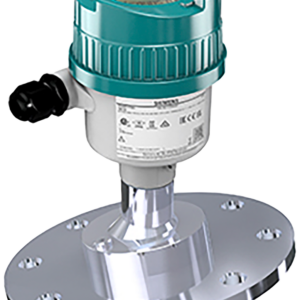

SITRANS LPS200

Contact

SITRANS LPS200 is a rotary paddle level switch for point level detection of dry bulk solids. It performs reliably in dusty, high-vibration industrial environments where mechanical durability is essential.

Categories: Level, Point Level Measurement, Rotation paddle switches

Brand: Siemens

Key Features

-

Proven rotating paddle technology for reliable level detection in bulk solids

-

High-quality sealed mechanical design ensures durability and protection against dust and moisture

-

Flexible power supply options, compatible with a wide range of systems

-

Special friction clutch protects the device from damage caused by falling material

-

Rotatable housing for easy installation and cable connection

-

Optional sensitive paddle for low bulk density materials down to 15.06 g/l (0.94 lb/ft³)

-

Compact paddle fits easily into existing process connections

-

Available in high-temperature and extended-length versions

-

Optional fail-safe detection in case of paddle stall, improving system reliability

-

SIL 2 certified, compliant with IEC 61508/61511 functional safety standards

Typical Applications

-

Level detection in grains, animal feed, cement, plastic pellets, sawdust, and other dry bulk materials

-

Suitable for use in silos, bins, hoppers, and heavy-duty industrial environments

-

Operates effectively even in low-density, adhesive, or high-vibration conditions

Operating Principle

A low-speed gear motor rotates the paddle. When no material is present, the paddle spins freely. When material covers the paddle, the movement is restricted and a microswitch detects this change, triggering an output signal. When the material level drops, the paddle resumes rotation and the relay resets to its original state.

The device’s adjustable sensitivity allows stable operation even with buildup on the paddle.

Optional Configurations

-

Available in standard, extended shaft, or rope extension versions

-

Paddle types include:

-

Standard paddle

-

Hinged paddle

-

Rectangular paddle for light materials

-

| Item | Specification |

| Mode of Operation | — |

| Measuring principle | Rotating point level switch |

| Input | — |

| Measured variable | High and low and demand |

| Output | — |

| Alarm output | Microswitch 5 A at 250 V AC, non-inductive Microswitch SPDT contact 4 A at 30 V DC, non-inductive |

| Pickup delay | • Standard (1 rpm model): approx. 1.3 seconds • Optional process applications (5 rpm model): approx. 0.26 seconds |

| Sensitivity | Adjustable via reset force of spring or geometry of measuring vane |

| Rated operating conditions | — |

| Location | Indoor/outdoor |

| Ambient temperature | –25 … +60 °C (–13 … +140 °F) |

| Storage temperature | –40 … +80 °C (–40 … +176 °F) |

| Installation category | III |

| Pollution degree | 2 |

| Medium | Bulk solids |

| Process temperature | • Standard: –25 … +80 °C (–13 … +176 °F) • Optional: –25 … +600 °C (–13 … +1112 °F) |

| Pressure (vessel) | • Standard: Max. 0.5 bar g (7.25 psi g) • Optional: Max. 10 bar g (145 psi g) |

| Minimum material density | • Standard measuring vane: Can detect down to 100 g/l (6.25 lb/ft³) • Optional measuring vane: Can detect down to 15.06 g/l (0.94 lb/ft³) |

| Design | — |

| Enclosure material | Epoxy coated aluminum |

| Process connection | Thread NPT, BSP, and flange options |

| Measuring shaft and vane | Stainless steel or aluminum |

| Degree of protection | IP65 / Type 4 / NEMA 4 |

| Conduit entry | 2 × M20 × 1.5 or 2 × ½” NPT (for FM and CSA approved versions only) |

| Power supply | — |

| AC or DC versions | • 115 V AC ±15 %, 50 … 60 Hz, 4 VA • 230 V AC ±15 %, 50 Hz, 6 VA • 48 V AC or 24 V AC, 2.5 W • 24 V DC ±15 %, 2.5 W |

| Universal voltage (DPDT relay) | 24 V DC ±15 % 50 … 60 Hz, 22 … 230 V AC ±10 %, max. 10 VA |

| Certificates and approvals | CSA/FM General Purpose, CE, CSA/FM Dust Ignition Proof, ATEX II 1/2 D, RCM, IECEx |

Related products

Continuous Level Measurement

Contact

Continuous Level Measurement

Contact

Level

Contact

Continuous Level Measurement

Contact

Continuous Level Measurement

Contact

Capacitance switches

Contact

Continuous Level Measurement

Contact

Level

Contact