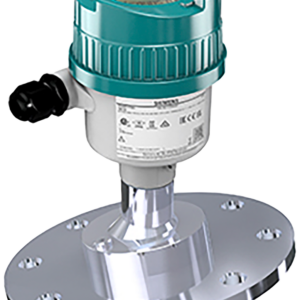

SITRANS LR530

Contact

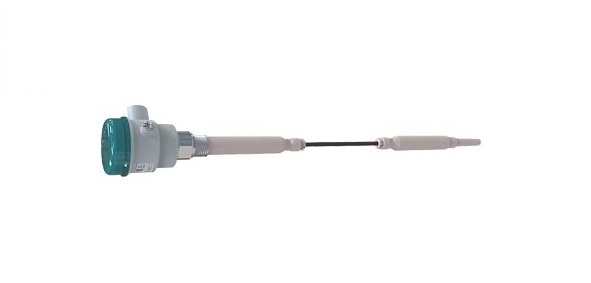

SITRANS LR530 is a radar level sensor for continuous measurement up to 120 m, featuring a sealed PTFE lens antenna with integrated gasket. It is ideal for corrosive liquids and hygienic applications in harsh environments.

Categories: Continuous Level Measurement, Level, Radar level transmitters

Brand: Siemens

Key Features

-

Continuous level measurement up to 120 m (393 ft) with ±1 mm accuracy (IEC 62828 compliant)

-

Fast commissioning via 4-button HMI, SITRANS mobile IQ app (Bluetooth), or SIMATIC PDM

-

Integrated graphical interface with echo profile display and backlight for on-site operation

-

Embedded IQ Guard for device health monitoring with NE107 diagnostics and quality inspection reporting

-

Advanced Process Intelligence ensures stable performance in noisy environments

-

Auto False Echo Suppression and Near Range Suppression to minimize interference from buildup or nozzle effects

-

Supports HART 7 digital communication

-

Low power consumption, with official Environmental Product Declaration (EPD)

-

Optional Second Line of Defense (SLOD) for enhanced safety in hazardous or toxic material applications

-

Built-in 100,000-point data logger for process optimization and analysis

-

Compliant with API 2350 for overfill prevention in dangerous liquid storage

Typical Applications

Designed for a wide range of industrial level measurement needs, including:

-

Liquids: chemical tanks, process vessels, water storage

-

Sludge: wastewater treatment and industrial processing

| Category | Specification | ||

| Measuring principle | Radar level measurement | ||

| Frequency | W band (80 GHz nominal) | ||

| Minimum detectable distance | 0 m from end of the antenna (antenna dependent, reference conditions) | ||

| HART | Version 7 | ||

| Analog output | 4 … 20 mA | ||

| Fail-safe | Programmable as high, low, or hold (loss of echo) | ||

| Update time | Up to 3 measurements per second | ||

| Maximum measured error | 1 mm (0.039 inch) | ||

| Influence of ambient temperature | Less than 3 mm/10 K and maximum ±5 mm over full range from -40 … +80 °C (-40 … +176 °F) | ||

| API standard | API 3.1B Inventory | ||

| Installation location | Indoor/outdoor | ||

| Ambient temperature (enclosure) | -40 … +80 °C (-40 … +176 °F) | ||

| Storage temperature | -40 … +80 °C (-40 … +176 °F) | ||

| Installation category | I | ||

| Pollution degree | 4 | ||

| Dielectric constant εr | > 1.6, antenna and application dependent | ||

| Weight | Range from 2 … 20 kg (4.4 … 44.1 lb), version dependent | ||

| Enclosure material | Aluminum, polyester powder-coated, C5 corrosion equivalent | ||

| Cable inlet | 2 x M20 x 1.5 or 2 x ½” NPT | ||

| Degree of protection | Type 4X, Type 6, IP66, IP68 | ||

| Local display | Optional graphical HMI with NE107 diagnostic data, echo profile display and backlight | ||

| Trend logging | 100,000 points, up to 8 variables including level, distance, space, volume, signal strength, confidence, temperature | ||

| Limit monitoring | Min/Max of 3 variables with count function | ||

| Terminal voltage | Available from HMI or EDD | ||

| Asset management | Diagnostic logbook, parameter change logbook | ||

| Power supply | Nominal 24 V DC (max. 30 V DC) with max. 800 Ω | ||

| Approvals – ordinary locations | FM, CCSAUS, CE | ||

| Approvals – radio | CE, FCC, IC, RCM | ||

| Hazardous area approvals | ATEX, IECEx, Intrinsically Safe Ex ia IIC T6 Ga ATEX, IECEx, Intrinsically Safe Ex ia IIIC Txx°C Da ATEX, IECEx, Dust Ignition proof Ex ta IIIC Txx°C Da ATEX, IECEx, CSA, FM, NEPSI, PESO, INMETRO EX II 1GD Ex ia IIC T6 … T4 Ga Ex ia IIIC T200 95°C Da Ex ia IIIC T200 135°C DaCSA/FM Intrinsically Safe Ex ia I, II, III, Div 1, Groups A, B, C, D, E, F, G T6 CSA/FM Non-Incendive Class I, Div. 2, Groups A, B, C, D T6 |

||

| Material certifications | 3.1 of EN 10204, NACE MR 0175 and MR 0103, 2.2 of EN 10204, PMI | ||

| Pressure certifications | CRN, PED | ||

| CRN – British Columbia | 0F7424.1 | ||

| CRN – Alberta | 0F22399.2 | ||

| CRN – Saskatchewan | 0F7424.13 | ||

| CRN – Manitoba | 0F7424.14 | ||

| CRN – Ontario | 0F7424.15 | ||

| CRN – Quebec | 0F7424.16 | ||

| CRN – Atlantic Canada and Territories | 0F1384.9870YNT | ||

| Programming via PC | SIMATIC PDM | ||

| SITRANS mobile IQ app | Optional AW500 Bluetooth module, for non-hazardous applications only | ||

| Category | Specification | ||

| Recommended measuring range | • DN 25: 20 m (66 ft) • DN 50, 2″: 30 m (98 ft) • ≥DN 80, 3″: 120 m (394 ft) Note: Maximum measurement range depends on the flange size, refer to the table in dimension drawings. |

||

| Process temperature | • Standard version: -60 … +150 °C (-76 … +302 °F) • Thermal extension version: -196 … +200 °C (-320 … +392 °F) |

||

| Process pressure | Process connection and temperature dependent. See Pressure/Temperature curves for more information. Note: Pipe applications are not recommended. For exceptions, contact Royal Technique technical support |

||

| Flange material | 316/316L stainless steel | ||

| Wetted materials – Antenna lens | PTFE lens with integral PTFE gasket | ||

| Process connection | Raised face, Form B1,

EN1092-1. DIN2501 |

Raised face, ASME B16.5 | Raised face, JIS |

| • Flange DN25 PN6

• Flange DN50 PN6 • Flange DN50 PN6 • Flange DN100 PN16 • Flange DN150 PN16 • Flange DN200 PN16 • Flange DN25 PN40 • Flange DN50 PN40 • Flange DN80 PN40 • Flange DN100 PN40 • Flange DN150 PN40 |

• Flange 1″ 150lb

• Flange 2″ 150lb • Flange 3″ 150lb • Flange 4″ 150lb • Flange 6″ 150lb • Flange 8″ 150lb • Flange 1″ 300lb • Flange 2″ 300lb • Flange 3″ 300lb • Flange 4″ 300lb • Flange 6″ 300lb • Flange 8″ 300lb |

• Flange DN25 5K

• Flange DN50 10K • Flange DN80 10K • Flange DN100 10K • Flange DN150 10K |

|

| Second line of defence option (SLOD)

|

Internal fused glass seal | ||

Related products

Level

Contact

Continuous Level Measurement

Contact

Level

Contact

Continuous Level Measurement

Contact

Continuous Level Measurement

Contact

Continuous Level Measurement

Contact

Level

Contact

Continuous Level Measurement

Contact