Key Features

-

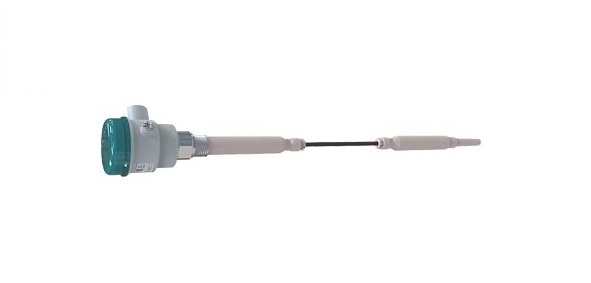

Proven vibrating level sensor technology, stable performance in liquid media

-

Ultra-compact design with a short probe (40 mm), ideal for installation in tight spaces

-

Starts at ½” threaded process connection, easy to retrofit into existing systems

-

Integrated fault monitoring functions for corrosion, loss of vibration, and broken piezo drive wire

-

Built-in functional testing capability for device status verification

Typical Applications

-

Level detection and monitoring of liquids and slurries

-

Used for overfill protection, high/low level alarms, and dry-run protection for pumps

-

Suitable for small pipes, narrow tanks, and space-constrained installations

-

Reliable in challenging conditions: foam, turbulence, air bubbles, coating, and external vibration

Operating Principle

The sensor uses a tuning fork driven by a piezoelectric actuator, vibrating at a mechanical resonant frequency of approximately 1,200 Hz. When the fork comes into contact with the medium, the vibration frequency shifts. The integrated oscillator detects this shift and converts it into a switching output signal. The onboard electronics process the signal and send control commands to connected systems.