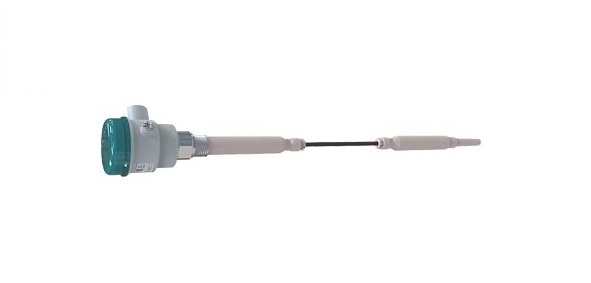

Key Features

-

High mechanical resistance, ideal for environments with impact and heavy vibration

-

Customizable probe length, easy to clean and adaptable to various installation configurations

-

Rotatable housing simplifies wiring and installation

-

Detects materials with bulk densities starting from 30 g/l (1.9 lb/ft³)

-

Probe extension available upon request, up to 4,000 mm (157.5 inch)

Typical Applications

-

Level detection of dry solids in the form of powders, granules, or bulk materials

-

Suitable for use in silos, bins, hoppers, and bulk handling systems

-

Applicable for high-level, low-level, or material load-dependent control

Operating Principle

An electrical signal activates a piezoelectric crystal in the probe, causing the vibrating fork to oscillate. When material covers the probe, the oscillation is dampened, and the electronics detect the change, triggering a relay output after an approximate delay of 1 second. When the material level drops, the fork resumes normal vibration and the relay resets.

The fork and crystal assembly is specially designed to prevent false high-level alarms, even when the tines experience minor wear.