Key Features

-

High mechanical strength, resistant to deformation from heavy material impact

-

Withstands strong vibration, ensuring signal stability in large silos or continuously vibrating environments

-

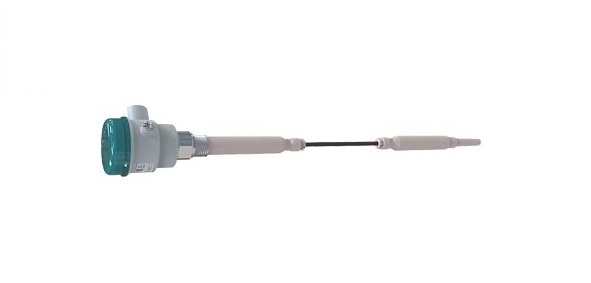

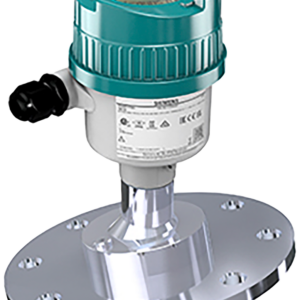

Rotatable housing for flexible wiring and easy installation

-

Accurate detection of low-density materials, standard from 20 g/l, optional down to 5 g/l

-

Short probe option: 165 mm (6.5 inch) for installation in tight spaces

-

Extendable probe length up to 20,000 mm (787 inch) upon request

-

Optional solid layer detection in liquids, ignoring the liquid phase

-

Optional 4–20 mA output for contamination/buildup monitoring

Typical Applications

-

Point level detection of dry bulk solids in bins, silos, and hoppers

-

Interface detection of settled solids in liquids

-

Ideal for constricted spaces such as feed pipes or vertical chutes

-

Environments with intense vibration, dust, or adhesive materials prone to buildup

Operating Principle

An electronic signal excites a piezoelectric crystal inside the probe, causing it to vibrate. When material covers the probe, the vibration amplitude is dampened. The electronics detect this change and activate a relay signal after a delay of approximately 1 second. Once the material recedes, vibration resumes and the relay resets.

The specialized design of the vibrating element and crystal minimizes false high-level alarms, even in cases of minor probe wear.