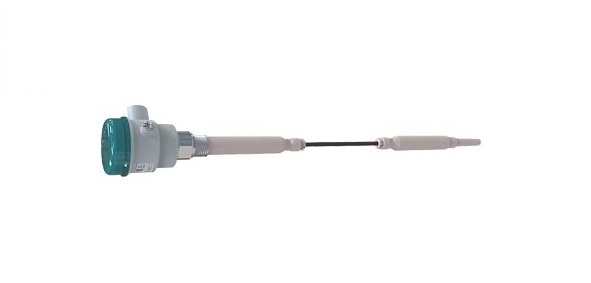

Key Features

-

High mechanical load resistance, ideal for heavy materials and harsh industrial environments

-

Adjustable sensitivity ensures reliable operation even in the presence of material buildup

-

Rotatable housing for easy cable routing and installation

-

Accurately detects low-density materials with standard sensitivity from 20 g/l (1.3 lb/ft³)

-

Standard probe length: 160 mm (6.3 inch); extendable up to 4,000 mm (157 inch) upon request

-

Supports user-supplied flexible rod extensions

-

Process connection from 1” thread, compatible with most existing systems

Typical Applications

Designed for dry bulk material detection, especially for materials prone to adhesion or bridging, such as:

-

Lime, molding powder, milk powder, flour

-

Salt, plastic pellets, recycled resin granules

Mountable in various orientations:

-

Top-mounted, side-mounted, or inclined installation

Operating Principle

An electronic signal activates a piezoelectric crystal inside the probe, causing the vibrating fork to oscillate. When the fork is covered by material, the vibration amplitude is dampened. The electronics detect this change and trigger a relay signal after approximately 1 second delay. When the probe is no longer covered, normal vibration resumes and the relay resets.

The unique fork and crystal assembly design helps prevent false high-level alarms, even in cases of minor tine wear.